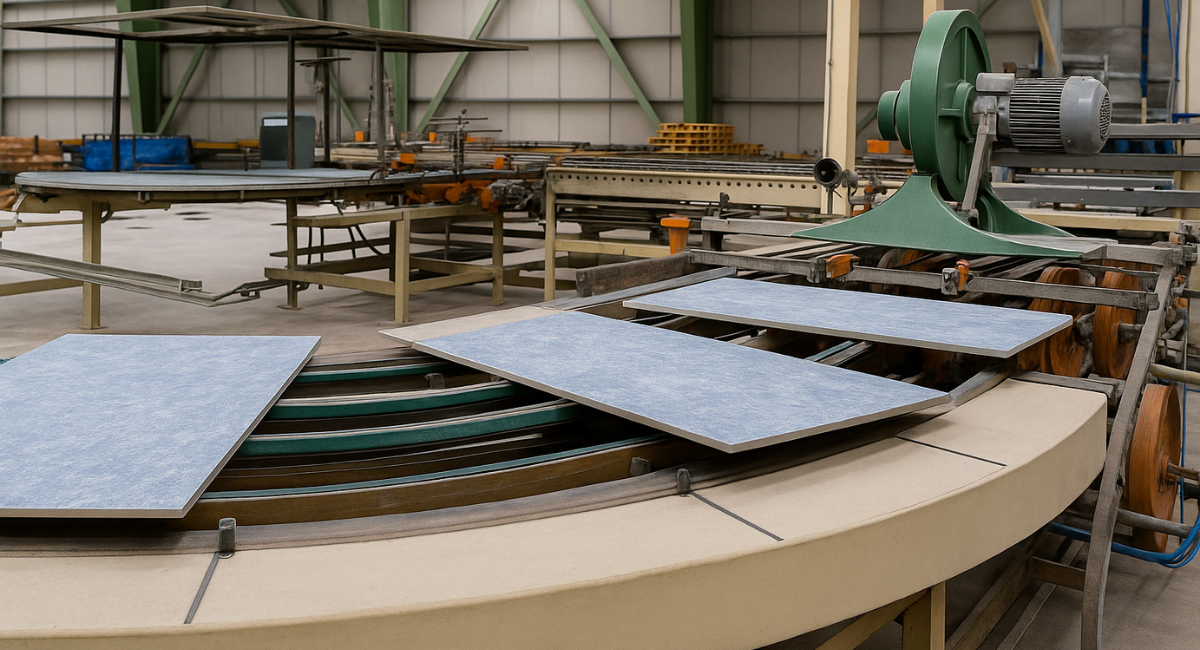

Porcelain is a ceramic material fired at very high temperatures, with a dense structure and an extremely low water absorption rate. The fundamental difference that separates it from conventional ceramics lies in the purity of its raw materials, the length of its production process, and the high firing temperature. When these three elements come together, the result is a material that is distinct both technically and aesthetically. The origin of porcelain is rooted in the need to produce surfaces that are durable yet refined. First developed in East Asia, it has gradually established a strong position in architectural and industrial applications. Today, porcelain is no longer considered merely a surface covering, but rather the expression of a long-lasting and controlled material choice.

Raw Materials That Define Porcelain

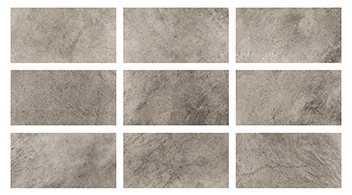

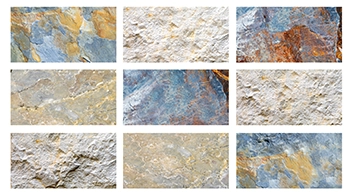

The primary components of porcelain are kaolin, feldspar, and quartz. Kaolin determines the whiteness and purity of porcelain. Feldspar melts at high temperatures, enabling the vitrification of the material. Quartz supports structural strength. When the proportions and quality of these raw materials change, the performance of the resulting porcelain changes directly. As raw material purity increases, porcelain density rises. As density increases, porosity decreases. Reduced porosity makes it more difficult for water and external factors to penetrate the material. For this reason, porcelain gains a structure capable of preserving its form and surface integrity for many years.

The Relationship Between High Temperature and Dense Structure

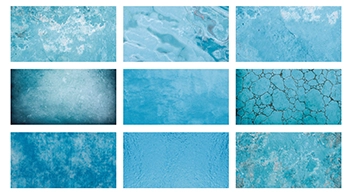

The high firing temperature applied during porcelain production is the most critical factor determining the internal structure of the material. Thanks to high temperatures, raw materials bond more tightly to one another, forming an almost glass-like structure. This vitrified structure is the main reason for porcelain’s low water absorption rate. As water absorption decreases, the material becomes more resistant to external conditions. Factors such as freezing, sudden temperature changes, or chemical exposure have a limited effect on dense porcelain surfaces.

This characteristic makes porcelain not only aesthetically refined but also technically reliable.

The Fundamental Difference Between Porcelain and Other Ceramic Types

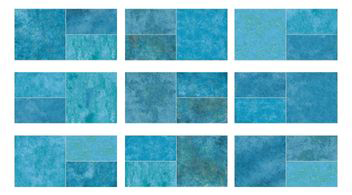

Every porcelain is a ceramic, but not every ceramic is porcelain. This distinction is often misunderstood or incompletely known. Ceramics are generally fired at lower temperatures and have a more porous structure. As porosity increases, the material becomes more vulnerable to external influences. Porcelain, on the other hand, undergoes controlled densification throughout its production process. This densification occurs not only on the surface but throughout the entire body of the material. For this reason, porcelain performance is not limited to a surface layer. It retains the same structural properties when cut, worn, or used over long periods.

The Technical Character of Porcelain

The technical character of porcelain is defined through measurable values. Water absorption rate is foremost among these. According to international standards, porcelain must have an extremely low water absorption rate. This characteristic ensures a hygienic material structure and reduces the risk of surface staining. Density and hardness determine porcelain’s mechanical strength. A hard structure lowers the risk of surface scratching and abrasion. At the same time, porcelain shows high resistance to chemical cleaning agents. This contributes to maintaining surface performance over the long term. For more information, you may read our article titled The Silent Power of Elegance: The Engineering of Porcelain .

The Balance Between Aesthetics and Continuity

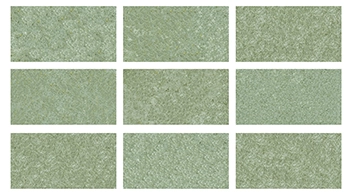

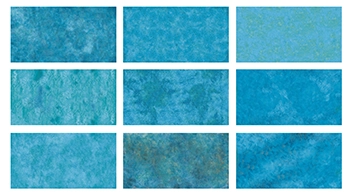

The technical strength of porcelain does not limit its aesthetic potential. On the contrary, its controlled production process makes surface texture, color depth, and visual continuity more predictable. Color is distributed consistently throughout the entire body of the material, not only on the surface. This consistency minimizes potential tone variations and surface degradation over time. Especially in areas of long-term use, porcelain’s ability to maintain an appearance close to its original state is directly related to this structural integrity.

Why Is Porcelain Considered a Long-Lasting Material?

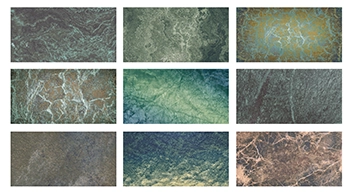

For a material to be considered long-lasting, durability alone is not sufficient. It must also be able to maintain its performance over time. Porcelain achieves this continuity through its resistance to both physical and chemical effects. Its structure, resistant to external factors, reduces maintenance requirements. Low maintenance needs contribute to the material remaining more stable throughout its lifespan. For this reason, porcelain is evaluated not as a short-term surface solution, but as a long-term material choice.

The Meaning of Porcelain as a Material

Porcelain stands out not only for its technical properties but also for the consistency it offers throughout production and use. The controlled progression of production stages makes the material’s long-term performance more predictable. This predictability also determines the extent to which the surface can preserve its original appearance. When evaluating surface materials, first impressions alone are not sufficient. Usage conditions, environmental exposure, and maintenance requirements over the years must also be considered. With its structure that responds to this long-term evaluation need, porcelain is positioned as a reliable option in architectural and design decisions.

.webp)